Dimensional Calibration

Dimensional measuring equipment refers to a wide range of instruments and devices used to measure the physical dimensions (such as length, width, height, diameter, angle, and depth) of objects, parts, or components. These tools are essential in industries like manufacturing, engineering, quality control, and construction to ensure that products and components meet specified tolerances and standards.

Calibration is performed by highly trained calibration officers and high-tech equipment to provide results that will give you confidence in the capabilities of your pressure measuring equipment.

Service includes:

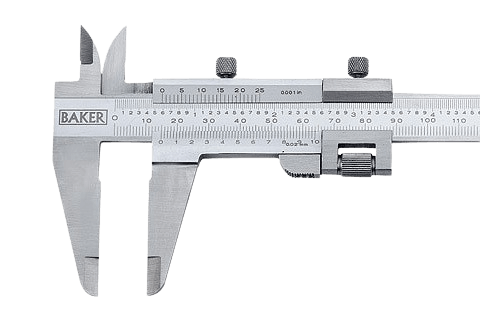

Caliper Calibration

Caliper is a versatile measuring instrument that can measure internal and external dimensions (e.g., length, width, depth) with high accuracy. It has a sliding scale that allows for precise measurements.

Calibration capability : up to 1000 mm

Outside Micrometer Calibration

Outside Micrometer is used to measure the external dimensions (like the thickness or diameter) of small objects with very high accuracy.

Calibration capability : up to 300 mm

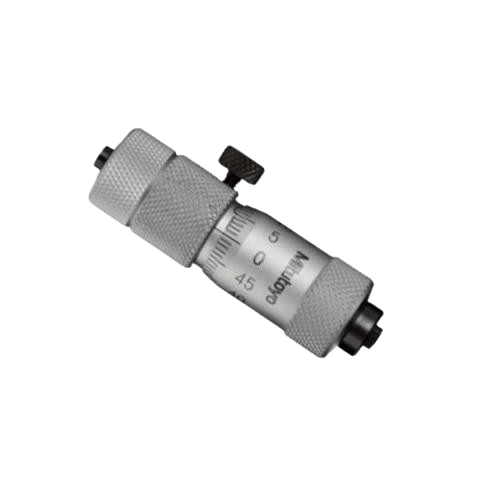

Inside Micrometer Calibration

Inside Micrometer is used for measuring internal dimensions such as the diameter of a hole or bore.

Calibration capability : 25~300 mm

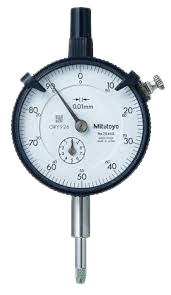

Dial Indicator Calibration

Dial Indicator is a measuring device that uses a needle and dial to measure small linear distances with great precision. It’s typically used for measuring runout, flatness, or displacement in machinery.

Calibration capability : up to 50 mm