Torque Calibration

Torque measurement is important in various industries and applications because it directly influences the performance, safety, and longevity of mechanical systems. Torque refers to the rotational force applied to an object, such as a bolt, shaft, or wheel, and is crucial for many processes, from assembly to operation and maintenance.

Calibration is performed by highly trained calibration officers and high-tech equipment to provide results that will give you confidence in the capabilities of your pressure measuring equipment.

Service includes:

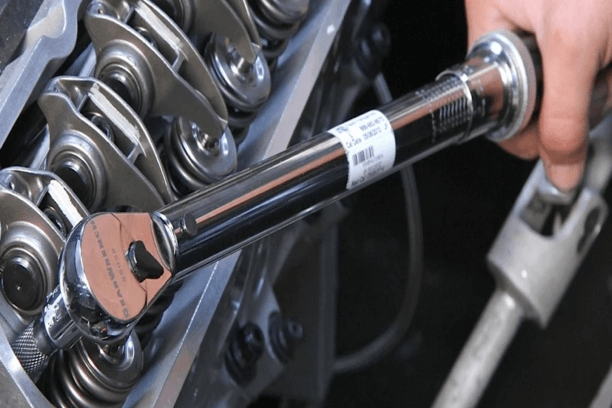

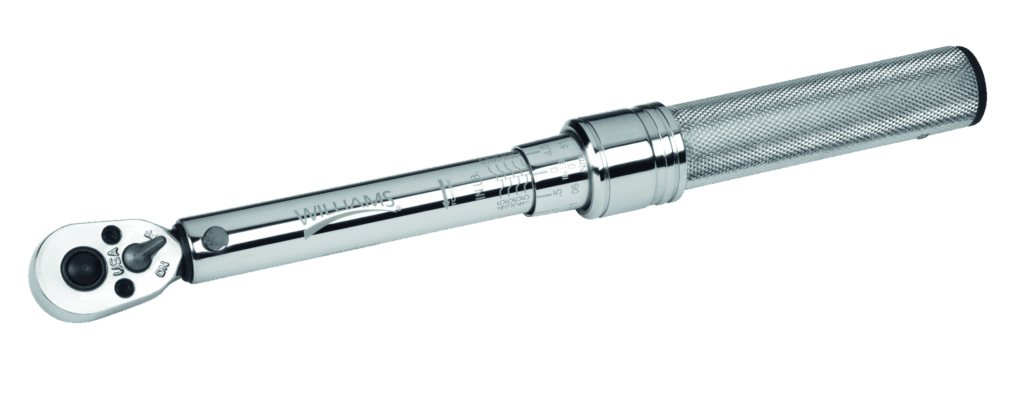

Torque Wrench Calibration

A torque wrench is a tool used to apply a specific amount of torque (rotational force) to a fastener, such as a bolt or nut, ensuring that it is tightened to the correct specification.

Calibration capability : up to 1000 N.m

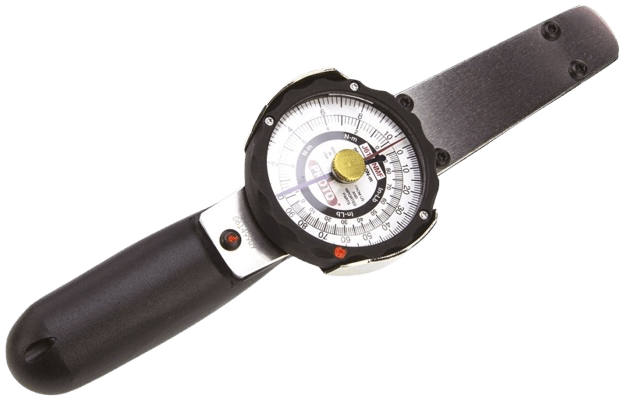

Dial Torque Wrench Calibration

A dial torque wrench is a type of torque wrench that uses a dial gauge to provide a visual reading of the applied torque. This allows the user to monitor and adjust the torque being applied to a fastener in real-time.

Calibration capability : up to 1000 N.m